For more anodized aluminum discs technical documents, Download free in PDF form !!

Anodized aluminum discs

Anodized Aluminum discs are Ultra-Durable Durable, anodized aluminum metal discs can be used outdoors or in harsh environments.Anodic oxidation or chemical oxidation is used to create a layer of oxide film on the surface of aluminum and aluminum alloy parts for protection and decoration.In order to overcome the defect for surface hardness and wear resistance and expand the application scope, prolong service life, surface treatment technology to become an indispensable part of aluminum alloy, and the anode oxidation technology is currently the most widely used and most successful.

Circle-shaped, Anodized Aluminum discs are color-coated on both sides and the edge for a durable protective finish! They make perfect metal labels for facilities management, color coded keys or quick identification of many types of objects.

Product Properties

TEMPER |

THICKNESS(mm) |

TENSILE STRENGTH |

ELONGATION% |

Standard |

||||||||||||||||

HO |

0.36-6 |

60-100 |

≥ 20 |

GB/T91-2002

|

||||||||||||||||

H12 |

0.5-6 |

70-120 |

≥ 4 |

|||||||||||||||||

H14 |

0.5-6 |

85-120 |

≥ 2 |

|||||||||||||||||

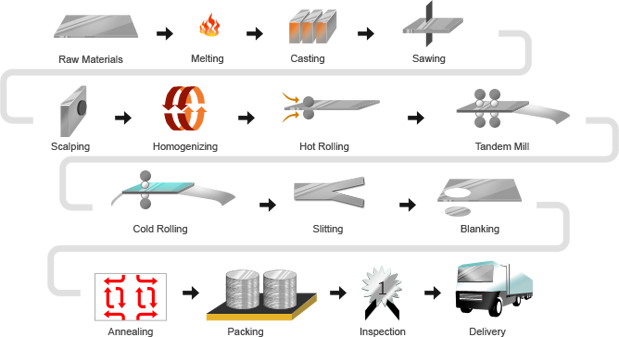

Product Process

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

Chemical Properties(WT.%)

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ca |

V |

Ti |

Other |

Min.A1 |

1050 |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.5 |

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.6 |

1070 |

0.25 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

- |

0.04 |

- |

0.05 |

0.03 |

0.03 |

99.7 |

1100 |

0.95 |

0.05-0.2 |

0.05 |

- |

- |

- |

0.1 |

- |

- |

- |

0.05 |

99 |

|

3003 |

0.6 |

0.7 |

0.05-0.2 |

1.0-1.5 |

- |

- |

- |

0.1 |

- |

- |

- |

0.15 |

96.95-96.75 |

Haomei anodized aluminum discs have excellent anodizing effect, stable performance, high surface quality, and can be applied for making high-grade cooking utensils. In the market, many people may find that the aluminum discs after anodized treatment has higher price than the ordinary aluminum discs. Here we must refers to the difference between anodized aluminum circles and aluminum circles discs.

The process of anodized aluminum discs has one more production progress, that is anodizing, after anodizing, the hardness and corrosion resistance of aluminum discs circles alloy will increase. Because the aluminum alloy do not have surface treatment is easy to be oxidized by the external factors, after the anodizing surface treatment, can improve the corrosion resistance, enhance wear resistance and hardness, protect the metal surface, etc. In addition, the aluminum film has a strong microporous adsorption capability and is favored by users after being colored into various beautiful beautiful colors, the typical application of anodized aluminum discs is high level colored cooking utensils. Haomei Aluminum can provide customized anodized aluminum circles for customers, all specifications are available, if you have any request, please contact us by email, we will give you quotation and reply as soon as possible.

FOB Reference Price:Get Latest Price

US $2,500-3,500 / Metric Ton | 2 Metric Ton/Metric Tons (Min. Order)

Supply Ability: 1000 Metric Ton/Metric Tons per Month

Port: Qingdao, Shanghai