For more round aluminum platee technical documents, Download free in PDF form !!

round aluminum plate

round aluminum plate products can be seen everywhere in our lives, for example, the cookware we use every day, the lamp cover at home and traffic signs on roads. We can say that the application of aluminum discs products is numerous, and many industries will use it, even aerospace equipment and some sophisticated electronic instruments.

Dimensions: A: 10" Material: Aluminum Grade: 7075 6061 Shape: Round

Product Properties

TEMPER |

THICKNESS(mm) |

TENSILE STRENGTH |

ELONGATION% |

Standard |

||||||||||||||||

HO |

0.36-6 |

60-100 |

≥ 20 |

GB/T91-2002

|

||||||||||||||||

H12 |

0.5-6 |

70-120 |

≥ 4 |

|||||||||||||||||

H14 |

0.5-6 |

85-120 |

≥ 2 |

|||||||||||||||||

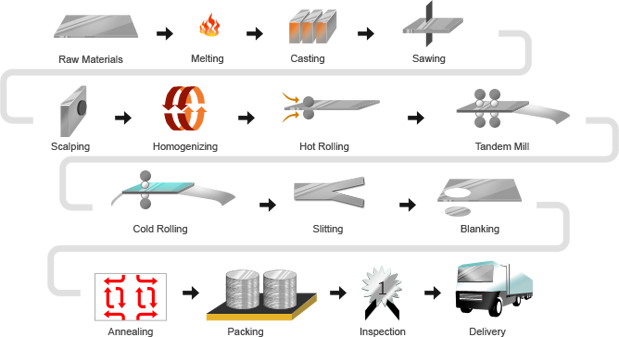

Product Process

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

Chemical Properties(WT.%)

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ca |

V |

Ti |

Other |

Min.A1 |

1050 |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.5 |

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

- |

0.05 |

- |

0.05 |

0.03 |

0.03 |

99.6 |

1070 |

0.25 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

- |

0.04 |

- |

0.05 |

0.03 |

0.03 |

99.7 |

1100 |

0.95 |

0.05-0.2 |

0.05 |

- |

- |

- |

0.1 |

- |

- |

- |

0.05 |

99 |

|

3003 |

0.6 |

0.7 |

0.05-0.2 |

1.0-1.5 |

- |

- |

- |

0.1 |

- |

- |

- |

0.15 |

96.95-96.75 |

haomei aluminium -China's largest round aluminum plate manufacturers and suppliers, the production of 1-8 series 10 inch aluminum circle,4 inch round metal plate to provide you with the best price and high quality services

Surface treatment methods forround aluminum plate mainly include anodizing, electroplating, infiltration, surface spraying, blast working and vacuum spraying.

Anodizing is to take advantage of the electrolysis principle of direct and alternating currents and get a layer of oxide film on the surface of a piece of round aluminum plate, making the sheet obtain stronger corrosion resistance and more attractive appearance.

Electroplating refers to the process of producing a solid cladding material attached stably on the surface of round aluminum plates by taking the wafers as the cathode while the material forming the cladding film as the anode. Both wafers and the material are placed in the bath with plating solution, and then the direct current or alternating direct current passes the solution, making the film forming material get ionized. Ionized material get attached firmly on the circle surface and become a film of the given thickness.

Infiltration is to have round aluminum plates in an immersion device for eight to ten hours during which dried compressed air is constantly forced into the device and make the pressure in it stable at around 0.4 Mpa. In the process the round aluminum plate are first cleaned by oil remover, and then washed by warm water between 25 to 30 degrees for heat preservation. After that, the sheets are placed into the immersion device which are sealed and vacuumed to 0.7 or 0.8 MPa. The temperature in the device should be kept at about 65 degrees, and then the prepared sizing is injected into the device for infiltration. Finally, infiltrated round aluminum plate are taken out and dried.

FOB Reference Price:Get Latest Price

US $2,500-3,500 / Metric Ton | 2 Metric Ton/Metric Tons (Min. Order)

Supply Ability: 1000 Metric Ton/Metric Tons per Month

Port: Qingdao, Shanghai